Book a meeting if you would like to know more about any of the services or solutions you have seen.

Your complete climate toolkit.

End-to-end carbon & utility management.

Our software solutions and consultancy services handle the most complex carbon and utility management challenges for any role in any industry.

Our clients have avoided

0,000,000kg of carbon emissions and saved

$0,000,000 in utility costs.

Trusted by outstanding businesses.

Let’s get started.

Something for everyone.

Whether you’re a sustainability leader, operations executive, property manager or CEO, our solutions offer you a complete climate tool kit.

Improve site performance, reduce operational costs, protect assets, and realise your path to carbon neutral with our trusted insights and expertise.

The monitoring and professional services that ESP provide have been invaluable in achieving our results. ESP Hub provides the visibility needed to productively plan and track performance across our entire portfolio.

Matt Rowbotham

GM Procurement and Property, ASB Bank

What’s your role?

How we can help you.

Whether you’re looking to maximise your organisation’s sustainability efforts or reduce operational utility costs, our range of leading carbon and utility software solutions can help you realise it.

Chief Executive & Directors.

Stay ahead of the curve. Retain access to business capital and attract top industry talent by proving your enterprise’s commitment to sustainability.

Production & Engineering.

Cut utility costs and improve the lifetime of critical equipment. Get complete oversight over operational utility use.

Property & Facility Managers.

Support asset management and control budget blowouts. Gain total visibility and access to measurable, meaningful building outcomes.

Sustainability Managers.

Identify significant sustainability wins and build better climate strategies with accurate, actionable data.

Client stories.

Don’t just take our word for it.

Here are just a few of the businesses around the world that have smashed their sustainability goals with ESP products and services.

Z Energy

Z’s purpose is to solve what matters for a moving world. At Z, we reckon sustainability matters and we’re committed to acting in a way that benefits the future of the communities we operate in. ESP provides the management tools for Z to achieve our goals.

Background

Z Energy (previously, Shell Oil New Zealand) is a retail fuel provider with over 300 sites throughout New Zealand. Each site is owned by one of 22 retail companies. Z Energy are a top 20 publicly listed company. They directly employ over 300 people and indirectly a further 2,200 through their retail network. They own a stake in New Zealand’s only refinery at Marsden Point and sell around 48% of New Zealand’s total transport fuel.

Challenge

The main challenge for Z Energy was managing its electricity, water and waste data. The company wanted to analyse and benchmark data at corporate, site and retail levels. To do this, they were using a combination of spreadsheets to complete the process.

Senior Management recognised that the existing data management and reporting process was not sufficient to do what they required and needed an urgent overhaul.

They sought a solution that provided a single view of the data with the functionality to analyse and report information at all levels within the organisation.

Outcomes

Z Energy engaged ESP (then BraveGen) in discussions for a possible solution for their data management and reporting requirements.

ESP provided a “proof of value” concept using historical data to demonstrate how our software would collect, aggregate and display their data.

Using ESP’s automated data collection systems and sophisticated Business Intelligence tools, Z Energy was able to increase the speed and accuracy of reporting and provide detailed reporting to key stakeholders.

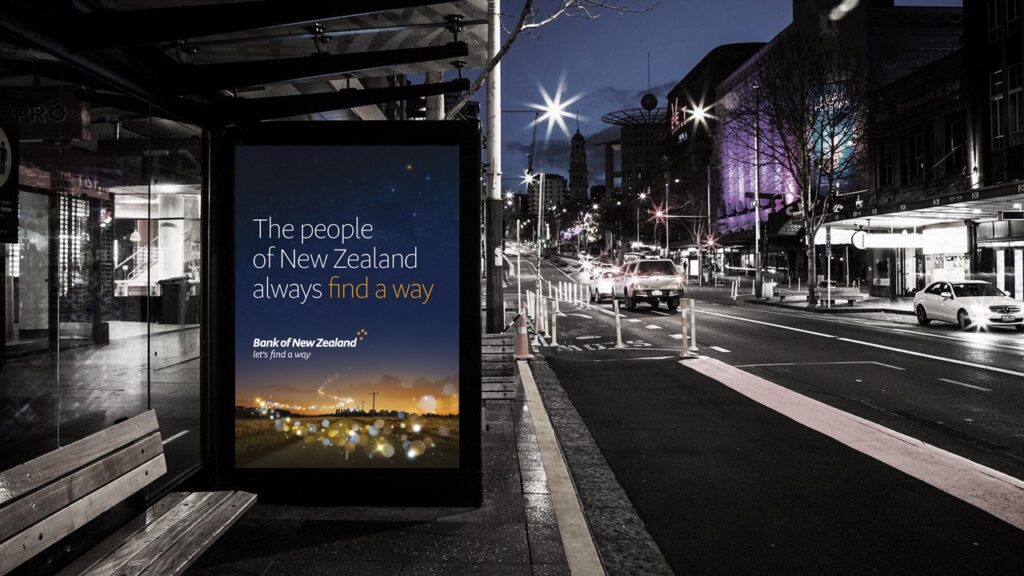

Bank of New Zealand

ESP accurately diagnoses one of the biggest pain points in sustainability, reporting and provides a viable, innovative, solution.

Background

Bank of New Zealand (BNZ) is one of New Zealand’s largest banks. It employs over 5,000 people and operates a nationwide network of 180 retail stores and business centres. BNZ must report its carbon footprint, energy use and water consumption twice yearly to its parent company.

Challenges

BNZ’s carbon capture and reporting process was heavily reliant on spreadsheets. There was immense time pressure at reporting time with only 6 weeks to gather all data from suppliers; collate, analyse and comment on trends; and submit individual spreadsheets on 15 different types of data.

Each spreadsheet had to contain all source data, emission factors, commentary and approval, and ensure the correct version of the file was being passed around.

Reviewing and approving the data was extremely time-consuming, unreliable, open to human error and in some cases wasn’t possible at all.

Management and board didn’t have confidence in the accuracy and reliability of the emissions report and figures presented to them

Outcomes

The bank has now visibility of the entire emissions profile, all of the emission sources, all of the base data, all of the emissions factors, and carbon dioxide equivalents.

BNZ is now able to perform analytical and historical comparisons at any level of detail the bank wants, to review it.

Utilizing a smart approval process and automated notifications ensures activity data from internal and external suppliers is received, reviewed and approved on time.

ESP, formerly BraveGen, completely transformed the process and provides BNZ with the level of governance and oversight to feel confident that the data is absolutely right.

Webstar

Challenge

The print industry is known for its tight margins. Webstar has utilised ISO as a framework to continuously measure, plan and improve for some time now. Energy, as one of manufacturings largest costs became a target for applying this process to ensure the business could measurable improve and sustain energy efficiency gains.

Solution

Webstar found ESP from the EECA website and soon identified the data-driven approach fitted well with their desired approach. ESP identified a range of quick wins and then looked to detailed monitoring of key plant to sustain those gains, and identify more.

Outcome

Results have beaten expectations, with 5.7% reduction within the first year and now cumulative savings of over $250,000 resulting. On top of this, production costs have reduced by an estimated $500,000.

Bayleys – Harbour Grounds

Challenge

The team at Bayleys manage the large property portfolio in Wynyard Quarter now named Harbour Grounds. The portfolio comprises 7 premium Auckland waterfront offices with 7,000 tenants occupying 88,000 sqm. With a change of ownership, Bayleys needed to rapidly get up to speed with the buildings performance and continue improving its value as required by the new overseas owners.

Solution

Bayleys access ESP’s suite of services including monitoring, continuous commissioning and audits to deliver a data driven energy management plan for the portfolio.

Outcome

Over the portfolio there has been an average improvement in energy efficiency of 32%, saving tenants over $3million in costs and avoiding 2,700 t CO2-e. Multiple buildings now have 4 star plus NABERSNZ ratings with further improvements underway.

WineWorks

Challenge

WineWorks have set a goal of improving sustainability, however to improve operational performance and reduce scope 2 emissions the team need to gain timely visibility of electricity, LPG and water consumption at their Malborough plant.

Solution

ESP completed a Type 2 energy audit and installed targeted electricity metering supported by EECA funding. The analysis identified a range of efficiency opportunities including lighting, compresed air, nitrogen and after hours usage. Detailed monitoring identified how production usage and other factors impacted energy use, allowing accurate businesses cases to be developed.

Outcome

A clear plan of improvement was established to deliver initial savings. In the first 12 months lighting was replaced and a preventative maintenance plan to regularly check and fix air leaks was put in place. Monitoring has also provided the information needed to demonstrate to staff the benefits of improved shutdown procedures and the ability to continuously monitor impact. In the first year savings of 5% were achieved with a further 15% to 20% planned in the near future with upgrades to the nitrogen system and air compressors. The site is also looking forward to the new dashboard, with energy efficiency featuring more strongly in manager and team leader objectives…sustainability integrated into business performance!

Chorus

Challenge

Chorus operate telecommunication sites right across New Zealand and had a goal of reducing costs and improving visibility

Solution

In 2015, ESP installed electrical sub-metering at 7 of Chorus’s core sites followed by Type 2 Energy Audit. This resulted in better energy use visibility and energy efficiency recommendations. In 2016, following the success of the initial work, ESP extended the retail metering rollout which allowed data from each of the 93 sites to be ingested into ESP’s advance data analytics platform. ESP have since then provided peak demand analysis, power use effectiveness tracking, energy alerts, regular steering group meetings to enable the asset managers to have complete visibility of their assets.

Outcome

The continuous energy efficiency engagement has resulted in a 16% reduction in energy usage since the start of the programme. ESP continues to work with Chorus to optimise energy and related costs at their sites.

CBRE

Challenge

CBRE have teams throughout the country, managing buildings on behalf of landlords. CBRE works to improve the value of the buildings managed however staying on top of large and distributed portfolios means the team need to be as productive as possible.

Solution

CBRE and ESP have worked closely for a number of years, continually auditing and monitoring an increasing range of buildings to ensure they are energy efficient. As landlords start to see the advantages a program of NABERSNZ ratings have started, meaning the CBRE portfolio can compete for high quality, including government, tenants.

Outcome

Having worked together for a while means the CBRE portfolio are achieving above average NABERSNZ results. The CBRE team are able to be more productive and can communicate the results to landlords, backed by proof, including the use of View, a set of live sustainability dashboards that provide instant and in-situ updates on the business’ sustainability journey so far.

ASB

Challenge

ASB has branches of various sizes located all around New Zealand. Traditional energy efficiency approaches werent working – the team just couldnt be everywhere at once. Despite a range of efficiency improvements being taken, energy use and costs kept rising.

Solution

Initial analysis identified significant opportunities for improvement – right from Dargaville in the North to Christchurch in the South. In 2012, as a market first, energy monitoring was installed at every ASB branch and Energy Management Plan implemented to target a 20% reduction initially.

Outcome

ASB’s early leadership in energy efficiency and carbon reduction has seen energy use across the entire portfolio decrease by a staggering 46%. ASB has utilised the data analytics of the ESP platform and the ESP engineering team to embed energy and sustainability into their every day business.

Auckland Council

Challenge

Managing 3,500 properties with a wide range of uses, distributed around Auckland with a small team is a huge challenge for Auckland Council. However with energy efficiency targets to meet the Council team needed to focus on achieving and sustaining gains through partnership.

Solution

The ESP energy and water monitoring solution was implemented at nearly 100 of the Councils largest, or most used buildings. The team is able to remotely identify and target improvements in the portfolio and be alerted when anomalous usage occurs. The system is now a core component of delivering to the corporate property portfolios emission reduction targets of 50% reduction by 2030 and net zero by 2050 from the Councils FY2018 baseline.

Outcome

The council have achieved energy savings of 11.73GWh (the amount ~1,035 households use each year), avoided 1,231 tonnes of CO2-e and are on track to save $1.5m per year in operating costs. Throughout Covid-19 the team was able to monitor key sites remotely, ensuring they were efficiently shutdown whilst still ensuring appropriate ventilation for their use.

Auckland Council has also invested in the use of View, providing up-to-date and digestible data on the business’s progress so far in sustainability.

University of Auckland

Challenge

Auckland University has a very large property footprint, with a large and dynamic population using the facilities for a wide range of uses. Managing the portfolio with a small team to deliver financial and decarbonisation results is a big challenge.

Solution

ESP was selected to monitor energy use across the entire portolio. Our software provides a consolidated view of all energy meter data with easy to navigation right from total portfolio down to the individual loads.

Outcome

As the team work through the massive change projects and daily challenges of managing such a diverse range of buildings, our software enables the team to quickly identify the results of the improvement, and maintenance work carried out every day – no matter how large or small.

Counties Manukau Super Clinic

Background

The Counties Manukau Superclinic is a modern dynamic building. Staff and patients need high levels of comfort and control over the internal environment. Unfortunately the building was performing poorly, with very high energy use per square meter.

Solution

An energy management plan laid out the solution which included detailed sub-metering on all utilities, along with the establishment of a continuous commissioning programme. Even small inefficiencies in an HVAC system can mean huge energy wastage over time.

“Because we use sub-metering to identify day-to-day fluctuations in our energy use, we can combine this with detailed interrogation of the BMS to pinpoint a problem when it pops up, fix it, and stop the energy wastage as it occurs.” Mark Davies, Energy Manager

Outcomes

The programme of monitoring and optimising the HVAC system at Counties Manukau SuperClinic saves hundreds of thousands of dollars in operational costs per year.

Wilson Hellaby

Challenge

Wilson Hellaby at their Auckland Site wanted to better understand their energy use in different areas of the plant. Additionally, they were keen to improve energy efficiency and reduce costs at their site.

Solution

ESP installed electrical submetering followed by ongoing consultancy services to engage with the site. ESP consultants regularly engage with site for after-hours review, steering group meetings, building business cases, and carry out detailed analysis of sub systems.

Outcome

In the last 4 years, the engagement has managed to achieve energy reductions of 11 million kWh equating to over $1 million. The site has not only reduced utility costs but also reduce maintenance costs.

Mobil Oil

Challenge

Mobil were looking for a way to reduce energy usage at 118 fuel stations across New Zealand. ESP benchmarked the sites according to type and provided a cost-effective solution for a monitoring and targeting programme.

Solution

A combination of retail and sub-load metering was installed at 20 fuel stations across the country. These sites were the most energy intensive. ESP carried out site reviews and set up frequent steering group meetings to review, track, and implement the actions that were recommended.

Outcome

The project has resulted in energy reduction of $440,000 since September 2017. ESP continue to monitor the sites as well as discuss new recommendations with Mobil to continue their energy efficiency journey.

IAG

Challenge

IAG were looking to achieve a NABERSNZ rating for their building at 1 Fanshaw Street, Auckland feeding into their energy efficiency and scope 2 carbon emission reduction. As a joint engagement Colliers, the Property Manager were also looking to improve asset value. The building originally had a 5-star NABERSNZ, however this had lapsed and energy usage was increasing at 9% per year.

Solution

Metering was installed to a standard that could achieve a Basebuild NABERSNZ rating. The metering provided visibility to optimise operation of the mechanical plant. ESP was engaged to complete a monitoring and targeting programme that identified energy and costs savings opportunities for the building.

Outcome

Working together, the building has now achieved a Basebuild NABERSNZ rating of 5.5 Stars rating. This rating is amongst one of the highest published basebuild ratings.

NABERSNZ – Bayleys House

The list of sustainable credentials for Bayleys House continues to grow with not one but two NABERSNZ ratings.

Background

Managed by a partnership of Australasian asset managers; 151 Property, and Bayleys Property Services, optimising building performance and offering healthy, comfortable workspaces for tenants is top of the agenda.

NABERSNZ assessments were sought for a variety of buildings as a means to ensure consistent, accurate and verifiable results across a broad range of criteria and to enhance sustainability.

Solution

ESP engaged with the building management partnership, utilising cutting-edge technology and monitoring software to quickly and efficiently secure strong NABERSNZ ratings for the properties. The ratings were a mixed of tenancy and basebuild.

Results

A collaborative sustainable approach between landlord, property managers and tenants has delivered a high 4.5 star NABERSNZ base building rating for Bayleys House in Auckland waterfront’s dynamic commercial VXV Precinct.

Realty group Bayleys, who leases its head office in the building, has also earned a 4 star NABERSNZ rating for its tenancy – reflecting its strong commitment to the environment.

NABERSNZ assessor Hong Lee says high quality mechanical services including a fresh air system with a connected heat pump, have been instrumental in the achievement of a 4.5 star NABERSNZ rating for Bayleys House. The integrated heat pump provides consistent heat efficiency and reduces the need for electrical heating to kick in when the building cools down in winter.

Bayleys House has 70 energy monitoring meters spread across the building.“We can monitor down to 15 minute segments of energy use and you can even see the impact on air conditioning services if a staff member comes to work at 3am,” says Hong.

He says well-designed tenancy office services including LED lighting and occupancy sensors which switch off after 30 minutes, have driven the 4 star NABERSNZ tenancy score for Bayleys head office. A regime of normal daytime working hours has also propelled the Bayleys head office’s optimum energy performance.

Bayleys House also features the use of View, allowing stakeholders and staff to instantly understand how far they’ve come – and how far there is to go – on their journey towards meaningful sustainability.

Vulcan Steel

Challenge

Vulcan steel had little visibility into energy usage at their site in Auckland. The site wanted assistance in sustained reductions in consumption and better data to make informed future investment decisions.

Solution

ESP installed sub-metering system followed by a Type 1 energy audit at the Auckland site identifying opportunities to improve machine utilisation, reduce compressed air usage, and upgrade lighting.

Outcome

This engagement has resulted in 25% savings in the first year alone. This was achieved with better shift management to double production levels from baseline year. The factory has also upgraded their lighting to LED. Vulcan Steel continues to engage ESP in tariff negotiation at other sites.

Webstar

Challenge

The print industry is known for its tight margins. Webstar has utilised ISO as a framework to continuously measure, plan and improve for some time now. Energy, as one of manufacturings largest costs became a target for applying this process to ensure the business could measurable improve and sustain energy efficiency gains.

Solution

Webstar found ESP from the EECA website and soon identified the data-driven approach fitted well with their desired approach. ESP identified a range of quick wins and then looked to detailed monitoring of key plant to sustain those gains, and identify more.

Outcome

Results have beaten expectations, with 5.7% reduction within the first year and now cumulative savings of over $250,000 resulting. On top of this, production costs have reduced by an estimated $500,000.

Z Energy

Z’s purpose is to solve what matters for a moving world. At Z, we reckon sustainability matters and we’re committed to acting in a way that benefits the future of the communities we operate in. ESP provides the management tools for Z to achieve our goals.

Background

Z Energy (previously, Shell Oil New Zealand) is a retail fuel provider with over 300 sites throughout New Zealand. Each site is owned by one of 22 retail companies. Z Energy are a top 20 publicly listed company. They directly employ over 300 people and indirectly a further 2,200 through their retail network. They own a stake in New Zealand’s only refinery at Marsden Point and sell around 48% of New Zealand’s total transport fuel.

Challenge

The main challenge for Z Energy was managing its electricity, water and waste data. The company wanted to analyse and benchmark data at corporate, site and retail levels. To do this, they were using a combination of spreadsheets to complete the process.

Senior Management recognised that the existing data management and reporting process was not sufficient to do what they required and needed an urgent overhaul.

They sought a solution that provided a single view of the data with the functionality to analyse and report information at all levels within the organisation.

Outcomes

Z Energy engaged ESP (then BraveGen) in discussions for a possible solution for their data management and reporting requirements.

ESP provided a “proof of value” concept using historical data to demonstrate how our software would collect, aggregate and display their data.

Using ESP’s automated data collection systems and sophisticated Business Intelligence tools, Z Energy was able to increase the speed and accuracy of reporting and provide detailed reporting to key stakeholders.

Mobil Oil

Challenge

Mobil were looking for a way to reduce energy usage at 118 fuel stations across New Zealand. ESP benchmarked the sites according to type and provided a cost-effective solution for a monitoring and targeting programme.

Solution

A combination of retail and sub-load metering was installed at 20 fuel stations across the country. These sites were the most energy intensive. ESP carried out site reviews and set up frequent steering group meetings to review, track, and implement the actions that were recommended.

Outcome

The project has resulted in energy reduction of $440,000 since September 2017. ESP continue to monitor the sites as well as discuss new recommendations with Mobil to continue their energy efficiency journey.

NABERSNZ – Bayleys House

The list of sustainable credentials for Bayleys House continues to grow with not one but two NABERSNZ ratings.

Background

Managed by a partnership of Australasian asset managers; 151 Property, and Bayleys Property Services, optimising building performance and offering healthy, comfortable workspaces for tenants is top of the agenda.

NABERSNZ assessments were sought for a variety of buildings as a means to ensure consistent, accurate and verifiable results across a broad range of criteria and to enhance sustainability.

Solution

ESP engaged with the building management partnership, utilising cutting-edge technology and monitoring software to quickly and efficiently secure strong NABERSNZ ratings for the properties. The ratings were a mixed of tenancy and basebuild.

Results

A collaborative sustainable approach between landlord, property managers and tenants has delivered a high 4.5 star NABERSNZ base building rating for Bayleys House in Auckland waterfront’s dynamic commercial VXV Precinct.

Realty group Bayleys, who leases its head office in the building, has also earned a 4 star NABERSNZ rating for its tenancy – reflecting its strong commitment to the environment.

NABERSNZ assessor Hong Lee says high quality mechanical services including a fresh air system with a connected heat pump, have been instrumental in the achievement of a 4.5 star NABERSNZ rating for Bayleys House. The integrated heat pump provides consistent heat efficiency and reduces the need for electrical heating to kick in when the building cools down in winter.

Bayleys House has 70 energy monitoring meters spread across the building.“We can monitor down to 15 minute segments of energy use and you can even see the impact on air conditioning services if a staff member comes to work at 3am,” says Hong.

He says well-designed tenancy office services including LED lighting and occupancy sensors which switch off after 30 minutes, have driven the 4 star NABERSNZ tenancy score for Bayleys head office. A regime of normal daytime working hours has also propelled the Bayleys head office’s optimum energy performance.

Bayleys House also features the use of View, allowing stakeholders and staff to instantly understand how far they’ve come – and how far there is to go – on their journey towards meaningful sustainability.

ASB

Challenge

ASB has branches of various sizes located all around New Zealand. Traditional energy efficiency approaches werent working – the team just couldnt be everywhere at once. Despite a range of efficiency improvements being taken, energy use and costs kept rising.

Solution

Initial analysis identified significant opportunities for improvement – right from Dargaville in the North to Christchurch in the South. In 2012, as a market first, energy monitoring was installed at every ASB branch and Energy Management Plan implemented to target a 20% reduction initially.

Outcome

ASB’s early leadership in energy efficiency and carbon reduction has seen energy use across the entire portfolio decrease by a staggering 46%. ASB has utilised the data analytics of the ESP platform and the ESP engineering team to embed energy and sustainability into their every day business.

Bank of New Zealand

ESP accurately diagnoses one of the biggest pain points in sustainability, reporting and provides a viable, innovative, solution.

Background

Bank of New Zealand (BNZ) is one of New Zealand’s largest banks. It employs over 5,000 people and operates a nationwide network of 180 retail stores and business centres. BNZ must report its carbon footprint, energy use and water consumption twice yearly to its parent company.

Challenges

BNZ’s carbon capture and reporting process was heavily reliant on spreadsheets. There was immense time pressure at reporting time with only 6 weeks to gather all data from suppliers; collate, analyse and comment on trends; and submit individual spreadsheets on 15 different types of data.

Each spreadsheet had to contain all source data, emission factors, commentary and approval, and ensure the correct version of the file was being passed around.

Reviewing and approving the data was extremely time-consuming, unreliable, open to human error and in some cases wasn’t possible at all.

Management and board didn’t have confidence in the accuracy and reliability of the emissions report and figures presented to them

Outcomes

The bank has now visibility of the entire emissions profile, all of the emission sources, all of the base data, all of the emissions factors, and carbon dioxide equivalents.

BNZ is now able to perform analytical and historical comparisons at any level of detail the bank wants, to review it.

Utilizing a smart approval process and automated notifications ensures activity data from internal and external suppliers is received, reviewed and approved on time.

ESP, formerly BraveGen, completely transformed the process and provides BNZ with the level of governance and oversight to feel confident that the data is absolutely right.

WineWorks

Challenge

WineWorks have set a goal of improving sustainability, however to improve operational performance and reduce scope 2 emissions the team need to gain timely visibility of electricity, LPG and water consumption at their Malborough plant.

Solution

ESP completed a Type 2 energy audit and installed targeted electricity metering supported by EECA funding. The analysis identified a range of efficiency opportunities including lighting, compresed air, nitrogen and after hours usage. Detailed monitoring identified how production usage and other factors impacted energy use, allowing accurate businesses cases to be developed.

Outcome

A clear plan of improvement was established to deliver initial savings. In the first 12 months lighting was replaced and a preventative maintenance plan to regularly check and fix air leaks was put in place. Monitoring has also provided the information needed to demonstrate to staff the benefits of improved shutdown procedures and the ability to continuously monitor impact. In the first year savings of 5% were achieved with a further 15% to 20% planned in the near future with upgrades to the nitrogen system and air compressors. The site is also looking forward to the new dashboard, with energy efficiency featuring more strongly in manager and team leader objectives…sustainability integrated into business performance!

Auckland Council

Challenge

Managing 3,500 properties with a wide range of uses, distributed around Auckland with a small team is a huge challenge for Auckland Council. However with energy efficiency targets to meet the Council team needed to focus on achieving and sustaining gains through partnership.

Solution

The ESP energy and water monitoring solution was implemented at nearly 100 of the Councils largest, or most used buildings. The team is able to remotely identify and target improvements in the portfolio and be alerted when anomalous usage occurs. The system is now a core component of delivering to the corporate property portfolios emission reduction targets of 50% reduction by 2030 and net zero by 2050 from the Councils FY2018 baseline.

Outcome

The council have achieved energy savings of 11.73GWh (the amount ~1,035 households use each year), avoided 1,231 tonnes of CO2-e and are on track to save $1.5m per year in operating costs. Throughout Covid-19 the team was able to monitor key sites remotely, ensuring they were efficiently shutdown whilst still ensuring appropriate ventilation for their use.

Auckland Council has also invested in the use of View, providing up-to-date and digestible data on the business’s progress so far in sustainability.

Vulcan Steel

Challenge

Vulcan steel had little visibility into energy usage at their site in Auckland. The site wanted assistance in sustained reductions in consumption and better data to make informed future investment decisions.

Solution

ESP installed sub-metering system followed by a Type 1 energy audit at the Auckland site identifying opportunities to improve machine utilisation, reduce compressed air usage, and upgrade lighting.

Outcome

This engagement has resulted in 25% savings in the first year alone. This was achieved with better shift management to double production levels from baseline year. The factory has also upgraded their lighting to LED. Vulcan Steel continues to engage ESP in tariff negotiation at other sites.

CBRE

Challenge

CBRE have teams throughout the country, managing buildings on behalf of landlords. CBRE works to improve the value of the buildings managed however staying on top of large and distributed portfolios means the team need to be as productive as possible.

Solution

CBRE and ESP have worked closely for a number of years, continually auditing and monitoring an increasing range of buildings to ensure they are energy efficient. As landlords start to see the advantages a program of NABERSNZ ratings have started, meaning the CBRE portfolio can compete for high quality, including government, tenants.

Outcome

Having worked together for a while means the CBRE portfolio are achieving above average NABERSNZ results. The CBRE team are able to be more productive and can communicate the results to landlords, backed by proof, including the use of View, a set of live sustainability dashboards that provide instant and in-situ updates on the business’ sustainability journey so far.

Chorus

Challenge

Chorus operate telecommunication sites right across New Zealand and had a goal of reducing costs and improving visibility

Solution

In 2015, ESP installed electrical sub-metering at 7 of Chorus’s core sites followed by Type 2 Energy Audit. This resulted in better energy use visibility and energy efficiency recommendations. In 2016, following the success of the initial work, ESP extended the retail metering rollout which allowed data from each of the 93 sites to be ingested into ESP’s advance data analytics platform. ESP have since then provided peak demand analysis, power use effectiveness tracking, energy alerts, regular steering group meetings to enable the asset managers to have complete visibility of their assets.

Outcome

The continuous energy efficiency engagement has resulted in a 16% reduction in energy usage since the start of the programme. ESP continues to work with Chorus to optimise energy and related costs at their sites.

IAG

Challenge

IAG were looking to achieve a NABERSNZ rating for their building at 1 Fanshaw Street, Auckland feeding into their energy efficiency and scope 2 carbon emission reduction. As a joint engagement Colliers, the Property Manager were also looking to improve asset value. The building originally had a 5-star NABERSNZ, however this had lapsed and energy usage was increasing at 9% per year.

Solution

Metering was installed to a standard that could achieve a Basebuild NABERSNZ rating. The metering provided visibility to optimise operation of the mechanical plant. ESP was engaged to complete a monitoring and targeting programme that identified energy and costs savings opportunities for the building.

Outcome

Working together, the building has now achieved a Basebuild NABERSNZ rating of 5.5 Stars rating. This rating is amongst one of the highest published basebuild ratings.

Bayleys – Harbour Grounds

Challenge

The team at Bayleys manage the large property portfolio in Wynyard Quarter now named Harbour Grounds. The portfolio comprises 7 premium Auckland waterfront offices with 7,000 tenants occupying 88,000 sqm. With a change of ownership, Bayleys needed to rapidly get up to speed with the buildings performance and continue improving its value as required by the new overseas owners.

Solution

Bayleys access ESP’s suite of services including monitoring, continuous commissioning and audits to deliver a data driven energy management plan for the portfolio.

Outcome

Over the portfolio there has been an average improvement in energy efficiency of 32%, saving tenants over $3million in costs and avoiding 2,700 t CO2-e. Multiple buildings now have 4 star plus NABERSNZ ratings with further improvements underway.

University of Auckland

Challenge

Auckland University has a very large property footprint, with a large and dynamic population using the facilities for a wide range of uses. Managing the portfolio with a small team to deliver financial and decarbonisation results is a big challenge.

Solution

ESP was selected to monitor energy use across the entire portolio. Our software provides a consolidated view of all energy meter data with easy to navigation right from total portfolio down to the individual loads.

Outcome

As the team work through the massive change projects and daily challenges of managing such a diverse range of buildings, our software enables the team to quickly identify the results of the improvement, and maintenance work carried out every day – no matter how large or small.

Wilson Hellaby

Challenge

Wilson Hellaby at their Auckland Site wanted to better understand their energy use in different areas of the plant. Additionally, they were keen to improve energy efficiency and reduce costs at their site.

Solution

ESP installed electrical submetering followed by ongoing consultancy services to engage with the site. ESP consultants regularly engage with site for after-hours review, steering group meetings, building business cases, and carry out detailed analysis of sub systems.

Outcome

In the last 4 years, the engagement has managed to achieve energy reductions of 11 million kWh equating to over $1 million. The site has not only reduced utility costs but also reduce maintenance costs.

Counties Manukau Super Clinic

Background

The Counties Manukau Superclinic is a modern dynamic building. Staff and patients need high levels of comfort and control over the internal environment. Unfortunately the building was performing poorly, with very high energy use per square meter.

Solution

An energy management plan laid out the solution which included detailed sub-metering on all utilities, along with the establishment of a continuous commissioning programme. Even small inefficiencies in an HVAC system can mean huge energy wastage over time.

“Because we use sub-metering to identify day-to-day fluctuations in our energy use, we can combine this with detailed interrogation of the BMS to pinpoint a problem when it pops up, fix it, and stop the energy wastage as it occurs.” Mark Davies, Energy Manager

Outcomes

The programme of monitoring and optimising the HVAC system at Counties Manukau SuperClinic saves hundreds of thousands of dollars in operational costs per year.